Starting point: the fixed assets file

It is essential to have a good fixed assets file before carrying out the physical inventory of fixed assets. A good fixed assets file also facilitates post-inventory reconciliation operations.

A quality fixed assets file must contain at least the following information:

- Clear, detailed wording: in our fixed asset inventories, we often come across unclear wording that makes it difficult to identify the assets concerned. For example: miscellaneous furniture, purchase and installation of technical equipment... The fixed assets file must be labelled in a way that corresponds to what physically exists: a desk, a chair, a split... This will enable you to know what needs to be inventoried in the field, and what name to use.

- Split lines: avoid grouping fixed assets on a single line. For example, 10 laptops; this will not make it easier for you to check out if, during the inventory, the quantity inventoried does not coincide with the theoretical quantity;

- Ancillary costs linked to the main asset: ancillary purchase costs must be linked to the main asset. We often see fixed asset lines relating to customs duties, transport, installation costs, etc., which are depreciated separately from the main asset. This practice makes it impossible to track the overall cost of the asset and its disposal.

- A location: ideally, the asset should be located within the company. You can use the name of the department, the owner or the office.

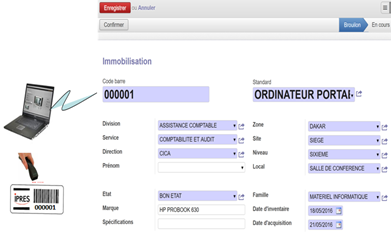

- A codification for each asset line; this may be the automatic codification of the asset management software.

The must-have: marking with non-tear barcode labels

Fixed assets need to be marked to prove that they belong to the company and to facilitate subsequent inventories. We often come across fixed assets marked with Dymo, indelible markers or paper labels.... Aside from aesthetics, this type of marking has its drawbacks:

- The label is easy to remove;

- The marking may fade over time;

- This does not necessarily facilitate a regular or rotating inventory of fixed assets.

- Etc.

Non-tearable barcode labels let you :

- Prove that the fixed assets belong to the company (with logo, specific mention, etc.).

- Facilitate regular stocktaking with a barcode scanner connected to asset inventory software (see our Inventory Control solution).

- Reconcile the physical inventory more easily with the theoretical fixed assets file.

Tools for physical inventory of fixed assets

You can, of course, use counting sheets to collect fixed assets in the field. However, processing and consolidation will be tedious: the items inventoried are not spelled in the same way, legibility if the counting sheets are handwritten...

Today, there are modern tools for collecting and marking fixed assets: software that embeds the nomenclature of fixed assets to be inventoried, along with the collection of all relevant fixed asset information. In fact, counting should not be limited to counting numbers, but should also collect relevant information on the asset: make, series, power, etc., which will enable you to obtain statistics on your assets.

Ideally, inventory teams should be equipped with barcode labels, a scanner and collection software to facilitate counting.

Organization and planning

In this respect, companies are relatively well organized:

- Composition of an inventory team (or commission). However, care must be taken when selecting the team, and it is important to select people who are familiar with the (technical) equipment, and to train them (often trainees) in inventory methodology;

- Circulation of an information notice specifying the dates on which the inventory teams will visit;

- Inventory instructions

The method: preferably blind

As with inventories, it is preferable to carry out the physical inventory of fixed assets blind, rather than from the accounting file. This method offers the advantage of speed, and ensures exhaustive counting and avoids omissions.

In this method, you need to be very careful about what is going to be inventoried; this is defined during team training and according to capital expenditure capitalization rules.

The inventory process

There are two possible scenarios: whether or not your fixed assets already have a barcode label

- If your fixed assets are already labelled with barcode labels, and you have a file with these barcodes, inventory will be very easy. With our fixed asset inventory application, you can quickly carry out the inventory by reading the labels affixed to the assets. At the end of the physical inventory, you can edit all the assets that are supposed to be present in the company and those that are not. You can quickly identify inventory discrepancies for analysis and decision-making.

- If your fixed assets are not labeled, this is an opportunity to do so at inventory time.

Would you like to entrust us with your inventory?

Metering control and reliability

At the end of the inventory, ideally, inventory sheets should be produced at least for the offices, and the occupants, managers or holders should check and sign them. Signing an inventory sheet helps to make staff aware of their responsibility for the safekeeping of assets.

Conclusion

A well-prepared physical inventory of fixed assets, with a well-equipped team (well-trained with software and barcode labels) can be child's play, and can even be carried out every year, depending on the size of the company.

About Moore Senegal

Moore Sénégal is a human-scale audit and consulting firm offering services tailored to the needs of businesses. We have proven expertise in fixed asset inventory: over 50 assignments completed, a fixed asset inventory and control tool, and a dedicated team for your projects.